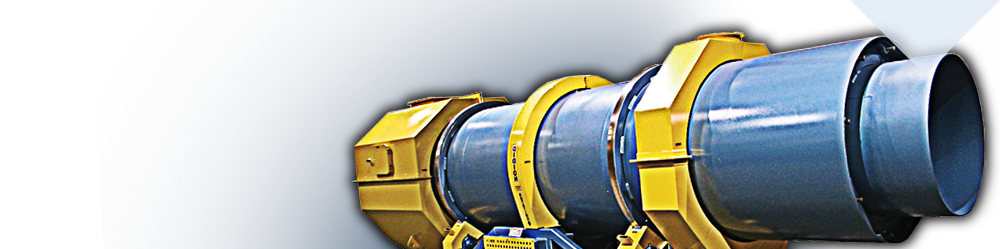

New Rotary Media Drum

New Rotary Media Drum Keeps Foundries Cleaner, More ProfitableReprinted with permission from FOUNDRY MANAGEMENT & TECHNOLOGY Rotary media drums® have saved foundries hundreds of thousands of dollars annually. The patented design has the lowest operating costs per ton in the industry worldwide. If you need to clean up your casting operation and increase your profit margin at the same time, the best place to start is to go directly to the areas that generate the most airborne silica dust. The primary source or biggest generator of dust is the vibrating shakeout and the sand carryover coupled with the amount of sand still attached to the castings - after shakeout. When a green sand mold is dumped onto a conventional vibrating shakeout, a huge amount of fine silica dust is released into the foundry environment. Since it is very difficult to capture all the steam laden with silica dust due to the amount of open area, the foundry environment becomes dirty. The amount of effluent is directly related to the sand temperature at shakeout. When the average sand temperature exceeds 100°C, the convection currents carry silica dust which is released into the foundry atmosphere. The higher the sand temperature at shakeout, the greater the convection current velocity and amount of steam and dust to be captured. With a sand to metal ratio lower than 6.9:1 the average sand temperature will exceed 100°C. The convection current velocity increases significantly from 100°C to 200°C (see chart 1.1 ). The heat affected zone of the mold is the area where the molten metal comes into direct contact with the sand grains (mold face). As the sand expands in this zone, internal stresses cause weak grains to fracture. Since the quality of the sand varies around the globe, the source of supply will have a direct impact upon fines generated from both mechanical and thermal aspects. Another important calculation tells us that for every kilo of metal poured into the mold 15% by weight of new sand should be added to replenish the losses and keep the sand system in balance. Since the amount of cores can vary from job to job, using core sand as new sand additions can be a hit or miss method unless it is separated from the green sand and then metered back in at a given rate. The second source of airborne silica dust is from the sand still attached to the castings after shakeout (in pockets, cavities, and corners). As the heat from the metal drives out the moisture, the loose sand falls off and contaminates downstream operations in the cleaning, finishing, and melting departments. Workers in these areas are exposed to silica dust from sandy metallics. The next source of dust comes from shot blasting these sandy castings. The sand that goes into the shot blast system not only accelerates wear of the equipment but is also degraded and added to the waste stream. This translates into increasing sand disposal costs. The sandy returns that go back to remelt without being shot blasted, lowers the melting efficiency and increases slag, slag handling, and slag disposal costs. Better Protection for CastingsThe machines are variable speed so the foundry can control the action. The media bed protects non-ferrous and fragile castings while cleaning and cooling the castings. Custom lining configurations are available for aluminum, brass, malleable, grey, ductile, and steel castings. Installations include green sand, shell, no-bake, and lost foam systems. Recent improvements featured in the Mark 5 Series include new interlock liners which are thicker and wider for longer life, 50% less seams and contoured rifling for delicate castings, self relieving tapered separation chambers, split pillow block endtrucks with quick change bearing inserts, and automatic chain tensioning. Faster CoolingSystem improvements include water quenching directly following the machine to eliminate long cooling conveyors further saving equipment costs, energy, time, and space. For foundries using casting baskets and stage cooling, water quenching following the Rotary Media Drum® can streamline production flow and eliminate the bottleneck in the cleaning room. To learn how DIDION Rotary Processing Equipment can improve the way you do business, please contact us today. |

|