Rotary Media Drums

The Safe, Clean, & Efficient Alternative to Vibratory Shakeouts

|

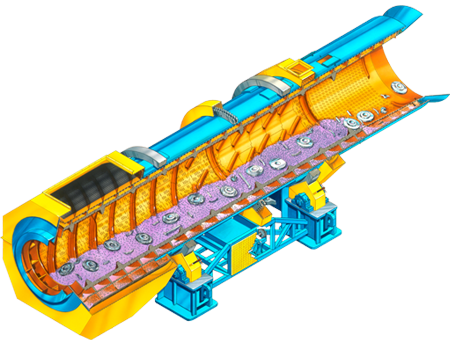

Forget shakeouts, call them rollouts. The DIDION Rotary Media Drum® has revolutionized the whole vibratory shakeout process. Now in use in 55 countries, the patented dual chamber design of the machine accomplishes many tasks in one easy step.

- First, it separates green sand from core sand and dramatically improves sand conditions.

- Second, it screens the sand, eliminating the need to buy and maintain more equipment.

- Third, it produces cleaner castings, greatly reducing shot blast time and reducing labor in the knockout and finishing departments.

- Fourth, it cools the castings enough to handle with gloves.

- And finally, it eliminates phone calls from irate neighbors claiming they just lost another family heirloom due to vibrations from your foundry.

The DIDION Rotary Media Drum® comes in ten standard sizes, or can be built specifically to your requirements. It is ideally suited for high speed, high pressure, flaskless molding systems. It can handle no-bake and shell moulding and can clean brass, bronze, ductile, gray, malleable, and steel castings.

Installation is a breeze - no pits or special foundations. Its efficient design has proven to reduce maintenance costs for many customers and it reduces air-borne silica dust from sand carryover for a cleaner, safer environment. It also eliminates stress problems and white caps in your coffee mug. So, next shut down or long weekend, remember... the only thing shaking in your foundry will be our competition. Forget shake, forget rattle, think roll.

Video

Related Articles

- DIDION MARK 5 Series Rotary Media Drums® keep foundries cleaner and more profitable.

- 70% Reduction in Shot Blast Time

- Buck Company Cleans Up Its Aluminum and Brass Casting Operations

- Cut Shakeout and Shotblast Costs

- Gartland Foundry Reduces Lead-Times and Costs with Didion Equipment

- Lee Brass Shines

- O-Z/Gedney Reduces Maintenance Costs by 90%

- Smith Foundry Company Modernizes Casting Operation

- MK5 Rotary Media Drum Provides Impressive Performance and Fast Payback