70% Reduction in Shot Blast Time

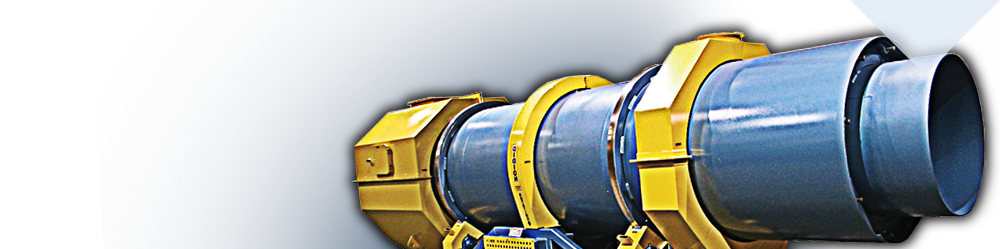

ALABAMA DUCTILE CASTINGS CO. (ADCCO). Brewton, AL. streamlined a bottleneck in its shakeout and cleaning operation with the installation of our MD-200 rotary media drum.

This high-production automotive foundry produces 1,000 molds an hour on three Disamatic molding machines. "A big emphasis was placed on how our 13-year-old foundry could deal with this material handling problem," said John Topping vice-president and general manager.

All three lines are fed into the drum which combines sand/casting separation, rotary sand screening, casting cleaning and casting cooling in one piece of equipment. Topping said the new equipment has produced several measurable improvements:

- Shot and blast time reduced 60% - 70% (from 20-22 minutes to 5 - 8 minutes)

- 60% - 70% reduction in power usage, shot consumption

- Reduced operating costs and maintenance including a 40% labor savings

- Cleaner castings, cool enough to handle with gloves

- Cleaner and quieter environment

To learn how DIDION Rotary Processing Equipment can improve the way you do business, please contact us today.