Revolutionizing Foundry Equipment since 1974

Rotary Carbon Separator / Thimble Cleaners

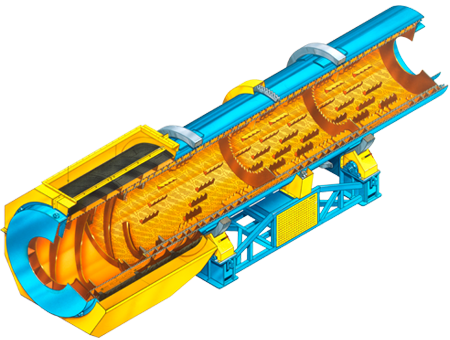

DIDION Rotary Carbon Separator / Thimble Cleaners utilize a highly efficient tumbling action for thorough cleaning of carbon from cast iron thimbles, including recesses for a cleaner melt. The patented design with segmented alloyed wear-liners provide lower noise, much better wear resistance, and ease of replacement. Cost savings include the elimination of shot blasting altogether, saving equipment, shot consumption, wear parts, maintenance time, floor space, and labor costs. The machine also serves as a horizontal storage silo with fully automatic feed of thimbles to reduce labor costs.

- Highly efficient tumbling action for thorough cleaning of carbon from cast iron thimbles, including recesses, for a cleaner melt.

- Cost savings include the elimination of shot blasting altogether, saving shot consumption and wear parts with less equipment, less floor space, less maintenance, less energy and less labor to increase efficiency and profitability.

- Simple, smooth drive system with very low energy consumption and low maintenance.

- Precision laser alignment of main support bearings for minimum wear.

- Reduced noise levels and dust escape due to containment in the drum.

- Very low dust collection CFM due to small open area.

- Very simple foundation requirements for minimal installation cost.

- Patented design with segmented cast wear liners provide lower noise, much better wear resistance, and ease of replacement.

- Simple adjustment of compression ring to maintain tightness of liner segments.

- Standard drive components.

- Ease of access to bearings and drive components.

Video

Related Case Study

Hillside Aluminum Gets Safer, More Effective, & More Efficient