Revolutionizing Foundry Equipment since 1974

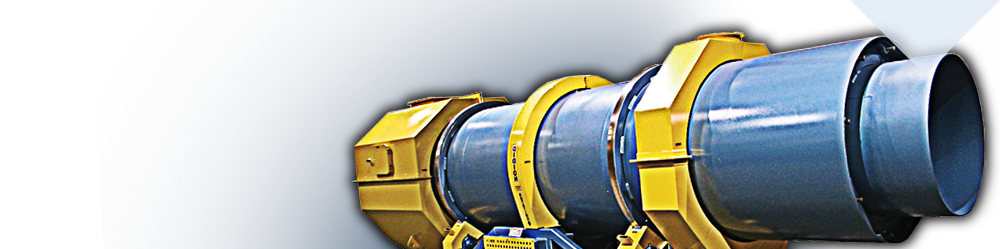

Rotary Sand Blending / Cooling Drums

These machines blend, cool, condition, screen, and classify green return sand efficiently to improve the sand system and increase production. You'll reduce scrap and cleaning costs with lower sand temperature and superior sand conditioning. Integral sand screening eliminates down stream screening equipment. Low energy consumption, low CFM requirements, minimum installation time and low operating cost increases profitability. Machine sizes range from 25 to 750 tons per hour of green sand.

- Reduces scrap and cleaning costs due to lower sand temperature and improved sand conditions.

- Provides more uniform sand to muller, improving muller efficiency and consistency of sand conditions.

- Rugged, durable construction requires minimum maintenance.

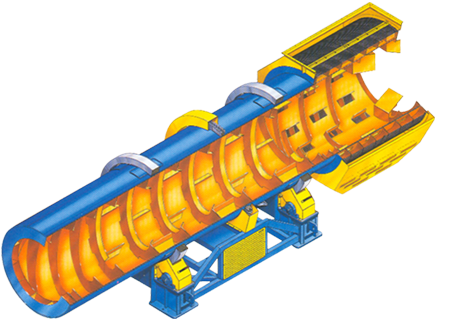

- Open end design with no center shaft allows for easy loading by feeder or chute.

- Simple, smooth drive system does not generate high frequency vibrations, thus eliminates the need for special foundations and large spare parts inventories.

- Precision laser alignment of the main support bearings allows the drum to run level, thus eliminates thrust loads and minimizes wear.

- Lifter bars and helical flights improve sand conditions by blending and mixing the sand.

- Integral sand screen.

- All drive components are standard, off-the-shelf items that are easily accessible.

- Low horsepower, low CFM requirements, minimum installation requirements and low operating costs are cost saving features.

- Easily adapted to programmed automatic control.