O-Z/Gedney Reduces Maintenance Costs by 90%

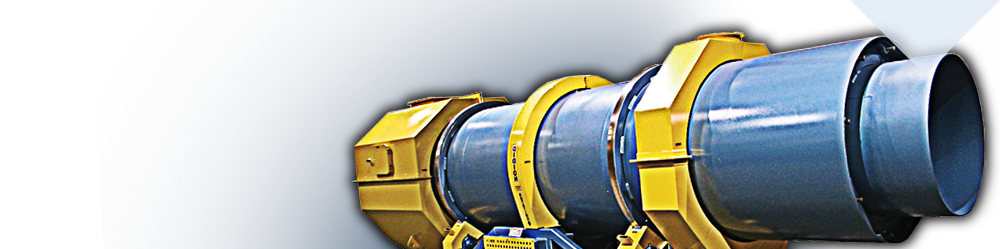

The O-Z/Gedney Company, an electrical fittings manufacturer in Terryville, Connecticut, found their DIDION MD-50 Rotary Media Drum® so superior to other shakeout systems that they immediately added two more machines after installing their first in 1989.

We installed the Didions after many attempts to handle our castings with several other types of shakeout equipment," said David J. Beaucar, plant manager. "We now have 3 DIDION drums handling each of our 3 DISAMATIC® lines and have reduced our maintenance costs by an astounding 90%."

Beside being costly to maintain, the other systems O-Z/Gedney experimented with caused high levels of scrap from breakage of the thin-walled malleable castings they produce. Incredibly, they were able to reduce casting breakage by 75% with the DIDION Rotary Drum.

- 30% reduction in cleaning costs and power usage

- Reduced shot blast time, shot consumption, and replacement parts

- Cleaner, cooler, and more consistent return sand

- Cleaner environment due to reduced noise, heat, and dust

- Castings that are cool enough to handle with gloves

To learn how DIDION Rotary Processing Equipment can improve the way you do business, please contact us today.