Metal Recovery Increases Savings

|

|

Fig 1. Slag Waste |

|

|

Fig 2. Resuable metal reclaimed from slag |

For years, an engineer at a medium-sized iron casting facility in the north central U.S. viewed the hundreds of tons of slag waste from its melting operation as an untapped piggy bank. It was no secret that useable metal was accompanying the slag from the cupola melting department to storage behind the facility, but they were too busy to consider reclaiming the metal from slag. Because it was easy to dispose of, the opportunity was shelved time and again. During the national economic downturn in 2008, a process efficiency team figured the time was right to tap into that piggy bank and realize the potential savings.

To guage the metal content in its slag waste, the metalcaster sent a sample for testing to DIDION International Inc., St. Peters, MO, which offers such services free of charge. When the initial results topped 60% useable metal content, the metalcasting facility sent two more samples to be sure the first wasn't taken from an unusually rich part of the waste.

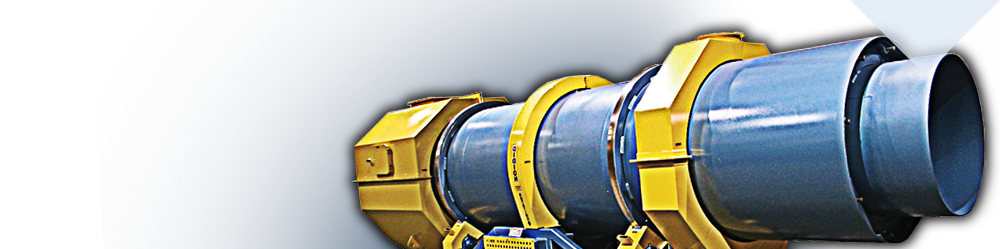

After the following two tests confirmed metallic reclamation rates above 60%, the facility purchased a DIDION Rotary Slag Separator / Metal Reclaimer with a variable jet burner and Conveyor Dynamics feed and discharge conveyors. The unmanned, stand-alone system was installed near the charging / melt department and designed with a dust-tight hopper to be front-loaded into a vibratory feeder that is metered into the Slag Separator / Metal Reclaimer.

The Slag Separator / Metal Reclaimer is a multi-chambered machine designed to crush and separate large chunks of slag from iron metallics. A crusher fractures the oxides, which are continually recirculated until they pass through the screening system. The metalcaster recouped its equipment cost in a matter of months.

Since installation, the metalcaster has reclaimed more than 2,000 tons of metal that otherwise would have gone into a landfill.

"When we started accumulating the waste, we couldn't give it away for free, much less sell it," said the facility's environmental engineer. "With the installation of the metal reclamation system, we have permanently increased our utilization of scrap and decreased our overall waste."

-Published in Modern Casting, December 2013

|

|

Fig 3. The Didion Rotary Slag Separator / Metal Reclaimer has reclaimed more than 2,000 tons of metal.

|