Revolutionizing Foundry Equipment since 1974

Rotary Sprue Crusher / Cleaners

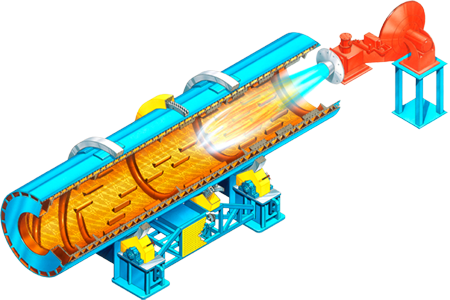

High rotary tumble action crushes core butts and cleans the sand off gates, runners, and sprue. Melting efficiency is increased with clean and condensed melting stock. The sand is recovered and slag handling and disposal costs are greatly reduced as well. The machine eliminates shot blasting of the melt returns and can process large mold/core lumps. Additional savings include the elimination of the cleaning room bottleneck as well as the need for expensive jaw crushers.

DIDION Rotary Sprue Crusher / Cleaners require less energy, less maintenance on shot blast equipment, and install easily. By helping keep the sand in the sand system, the machines also significantly reduce clean up costs and keep ones foundry much cleaner.

|

Intake view of the feed end of a 25 ton per hour Rotary Sprue Crusher / Cleaner. This machine is designed to aggressively tumble gates and runners scrubbing the sand from the metal and separating the sand and metal. The discharged sprue is clean and ready for remelt. |

|

Discharge view of the discharge end of the same machine above. |

|

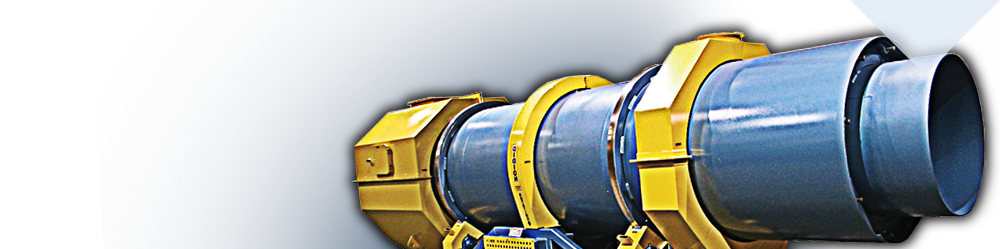

Two DIDION Model RS-200/SM Rotary Sprue Cleaners in use at a high production automotive foundry in Mexico. |