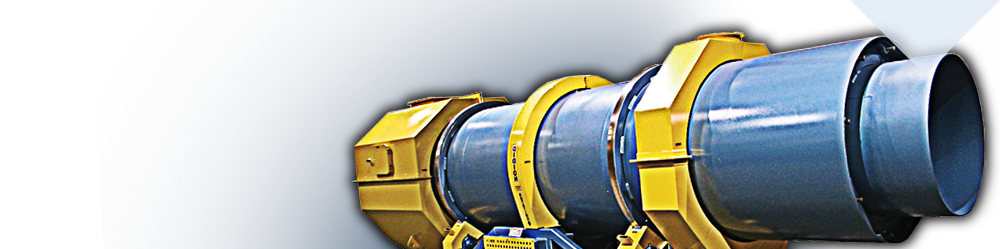

Rotary Dross / Slag Metal Reclaimers

Dross & Slag Metal Reclamation Systems

|

|

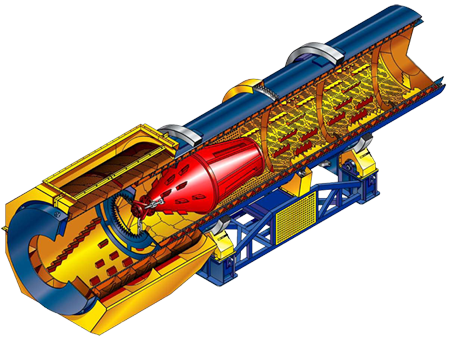

DIDION Rotary Dross / Slag Metal Reclaimers liberate and reclaim valuable metallics from large slag & dross chunks using a patented design. The machine features a Dynamically Isolated Articulated Concentric Crusher with serrated teeth that provides a positive action for reducing large chunks. The material is first screened in an aggressive attrition chamber through an extra heavy-duty cast alloyed wear-resistant liner which is two inches thick for long life. The material is tumbled again in the Star Chamber and then enters the final screening system where the slag & dross is separated and air classified from the reclaimed metal.

Metal Reclamation & Slag Recycling

The DIDION Rotary Dross / Slag Metal Reclaimers are being used to reclaim metal from dross, slag, salt cake, skimmings, spillage, and pot liner in the following materials:

- Aluminum

- Brass

- Bronze

- Copper

- Iron

- Nickel

- Steel/Stainless

- Specialty Alloys

Features & Benefits

- Patented design crushes, cleans, separates, and screens to reclaim valuable metals from slag, dross, salt cake, skimmings, spillage, and pot liner.

- Rotary tumble action provides excellent slag & dross reduction and separation for cleaner metallics and a cleaner melt.

- Positive crushing action with patented crushing roller to break down very hard lumps, yielding higher output.

- Dynamic Suspension System directs the energy of the crushing roller into the material, not the machine, utilizing an innovative isolation design.

- Attrition chamber utilizes serrated tooth lifters and high tumbling action, separating the slag & dross to liberate.

- Automatic recirculation of screen overs provides additional crushing for higher output.

- Extra Heavy Duty Design for 24/7 continuous operations.

- Precision laser alignment of main support bearings for minimum wear.

- Simple one point hookup of ductwork to supplied flanged opening.

- Automatic discharge of clean metal out the discharge end.

- Very efficient air wash for maximum dust separation.

- Very simple foundation requirements for minimal installation cost.

- Low operating cost with no compressed air or other additional energy sources required.

- Patented segmented cast wear liners provide lower noise, much better wear resistance, and ease of replacement.

- Standard drive components with easy access.

- Variable retention time for various materials to be processed/cleaned.

Video