Cut Shakeout and Shotblast Costs

|

| The foundry stays clean and safe by cleaning the castings during shakeout stage |

|

| Clean, cooled and degated castings from the DIDION Mark 5 being inspected |

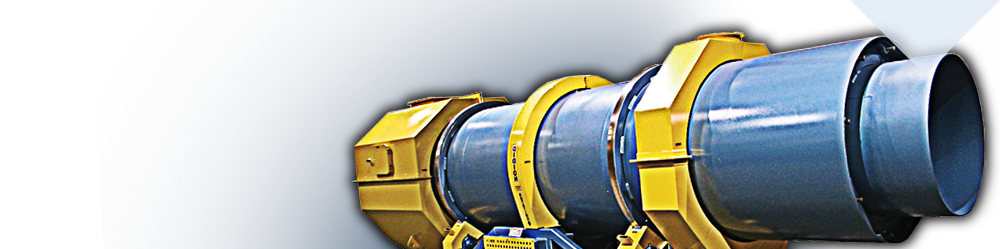

The Didion Mark 5 Rotary Media Drum® significantly lowers cleaning and finishing costs.

A lot of foundries have solved the bottleneck problem in the cleaning and finishing departments by first updating their shakeout system. The amount of sand carryover as well as the sand adhering to the castings is the single biggest factor relating to shotblast costs (labour to operate, shot consumption, energy consumption, replacement wear parts and maintenance time).

By reducing the sand from going into the casting cleaning department and helping keep it in the sand system where it belongs, the benefits go right to the bottom line. In addition to saving on all the above shotblast cost, other savings include less wear on the dust collectors, less waste streams, less airborne silica dust, and less clean up time.

When the castings are pre-cleaned in the shakeout system, the cleaning/finishing bottleneck is eliminated. Couple the pre-cleaning with casting cooling and the production flow is really streamlined.

Having cleaned gates, runners, and sprue from the shakeout department that goes directly to the melt department greatly relieves the cleaning department bottleneck. If the gates, runners, and sprue are too great a burden to shotblast, then the melting department faces excessive slag build up, reduced furnace lining life, and lower melting efficiency. The savings in the melting department alone can easily justify the need to have clean returns directly from the shakeout department. Cleaner melting, finishing, and shakeout areas all add up to a better and safer workplace.

Saint Gobain Pipelines, Sinclair Works in Telford, UK, improved its shakeout and finishing operations by installing a DlDlON Rotary Media Drum® to eliminate shotblasting altogether. The Mark 5 Rotary Media Drum® processes sand and castings from a DlSA vertically parted moulding line. The sand is separated from the castings and is screened twice to -9mm in the DIDION. All the metallics are thoroughly cleaned by a recirculating bed of prismatoid media which also protects and cools the castings. Upon discharging from the DIDION, the castings are submerged into a water quench for final cooling.

The clean and cooled castings are automatically conveyed to the grinding stations in the finishing department. The clean gates, runners, and sprue go directly back to the melting department.

This streamlined approach has been so successful that the foundry has ordered DIDION's latest Mark 5 Series Rotary Media Drum® for installation in summer 2003.

The Mark 5 design is even more robust with several new features such as; external sand screening, automatic chain tensioner, split pillow block design with quick change bearing inserts, duplex chain, thicker liners with contoured rifling, cast-in dam retention rings, and a self relieving tapered media separation chamber for fragile castings.

Several other foundries in the UK that have benefited from DIDION's New Mark 5 Series machines include; Castings PLC, Vald Birn, Wm Lee Ltd, and Triplex Foundry Ltd.

Combining sand casting separation, dual sand screening, and casting cleaning and cooling has proved so successful that paybacks are calculated in 4 - 5 months. The foundry also has less capital equipment to purchase, install and maintain. Less equipment means less dust collection requirements and less daily energy consumption.

Currently DlDlON International has the New Mark 5 Series Rotary Media Drum® in 42 countries worldwide.

The machines are custom designed to handle aluminium, brass, bronze, ductile, grey, and steel castings. Green sand, shell, lost foam, and no-bake foundries have all benefited from this unique patented approach.

United Machine and Foundry (UMF) in Minnesota, USA, installed a new DlDlON Mark 5 Series Machine and UMF director of operations Steve Renk, describes the benefits the company has achieved.

"With the installation of our new MK5 Rotary Media Drum®, we have improved three facets of the UMF operation - safety, quality, and productivity. Improvements in these areas are critical to our ability to succeed in the ever competitive foundry industry. The DlDlON gives us an advantage over competitors." He says.

"Prior to installing our new equipment we operated a vibratory shakeout system," said Mr. Renk. "A man running this piece of equipment was pretty much sentenced to work in hell. A number of employees left over the years from the simple fact that the job was too barbaric. Standing over a vibrating shakeout, trying to hook castings and place them in tote boxes is difficult and it is compounded by dust, steam, and heat. By installing the Mark 5, we have eliminated a safety hazard."

Mr. Renk says the company has realised quality improvements too. "The Rotary Media Drum's® ability to blend hot sand and cool sand has benefited our sand system. With the vibratory shakeout, the sand storage system had layers of hot sand on top of layers of cool sand, making the compactibility of the sand difficult to control. The new system has helped reduce big swings in sand temperatures, thus allowing our compactibility controller to run much more efficiently".

"Productivity gains and reduced costs have proved to be an added bonus for UMF operations. Many of the castings that we produce are no longer shotblast. UMF has reduced the man hours in shotblast and reduced operating hours on the maintenance intensive shotblast machines, which has allowed us to use production and maintenance personnel more effectively. We have significant annual savings from reductions in labor, sand disposal costs, shot purchases, accidents and maintenance/repair costs.

World class casting producers in the USA such as Waupaca Foundries, Wescast, Intermet, Grede, and Victaulic have modernized their shakeout/cleaning operations with Mark 5 DlDlON Rotary Media Drums®. Ductile iron castings with difficult or tough gating systems for workers trying to remove manually are automatically degated in the DIDION. The labor savings for this difficult and dangerous job alone have cost justified the modernized shakeout department.

Approximately 20% of the cost to produce a casting comes from shakeout, fettling, and cleaning. By combining shakeout, sand screening, casting cleaning and casting cooling, ferrous foundries can easily reduce these costs by 50% and save US $80 per ton.

To learn how DIDION Rotary Equipment can improve the way you do business, please contact us today.